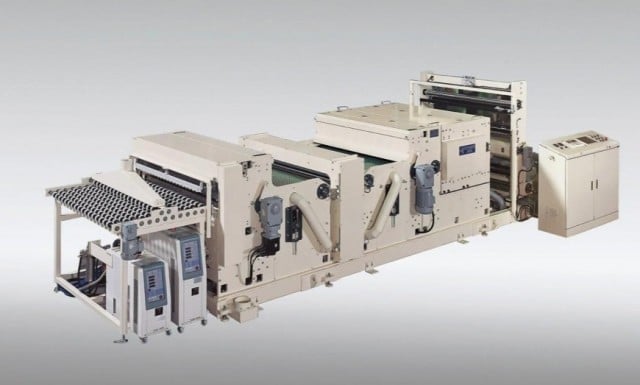

Equipment for which press technology is applied and specialized for various industries

Applying our unique pressing technology, we develop and manufacture equipment for cutting prepregs (carbon fiber in which unset thermosetting resin is impregnated), laminating IC cards and continuously laminating printed circuit board materials. We deliver equipment related to laminating and specialized for each industry to the world.