CFRP (carbon fiber reinforced plastic) is a composite material that has attracted the attention of the aviation industry, aerospace industry and the automobile industry as a new material. By reinforcing the resin with carbon fiber, not only is it lightweight but it is high in strength and has a stiffness higher than resin itself. CFRP laminates are manufactured by stacking sheets called prepregs that are made of carbon fibers impregnated with resin.

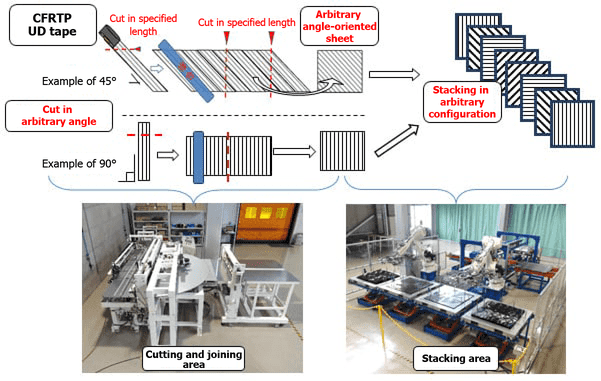

CFRP automatic stacking machine

This is an automatic stacking machine for carbon fiber reinforced thermoplastic resin (CFRTP) unidirectional continuous fiber (UD tape) materials.

It consists of two units of [cutting and joining area] to fabricate “arbitrary angle-oriented sheets” (800 to 1,200 mm square) with fiber orientation of arbitrary angle from UD tape and [stacking area] which can stack the fabricated “arbitrary angle-oriented sheets” in any arbitrary configuration.

It consists of two units of [cutting and joining area] to fabricate “arbitrary angle-oriented sheets” (800 to 1,200 mm square) with fiber orientation of arbitrary angle from UD tape and [stacking area] which can stack the fabricated “arbitrary angle-oriented sheets” in any arbitrary configuration.

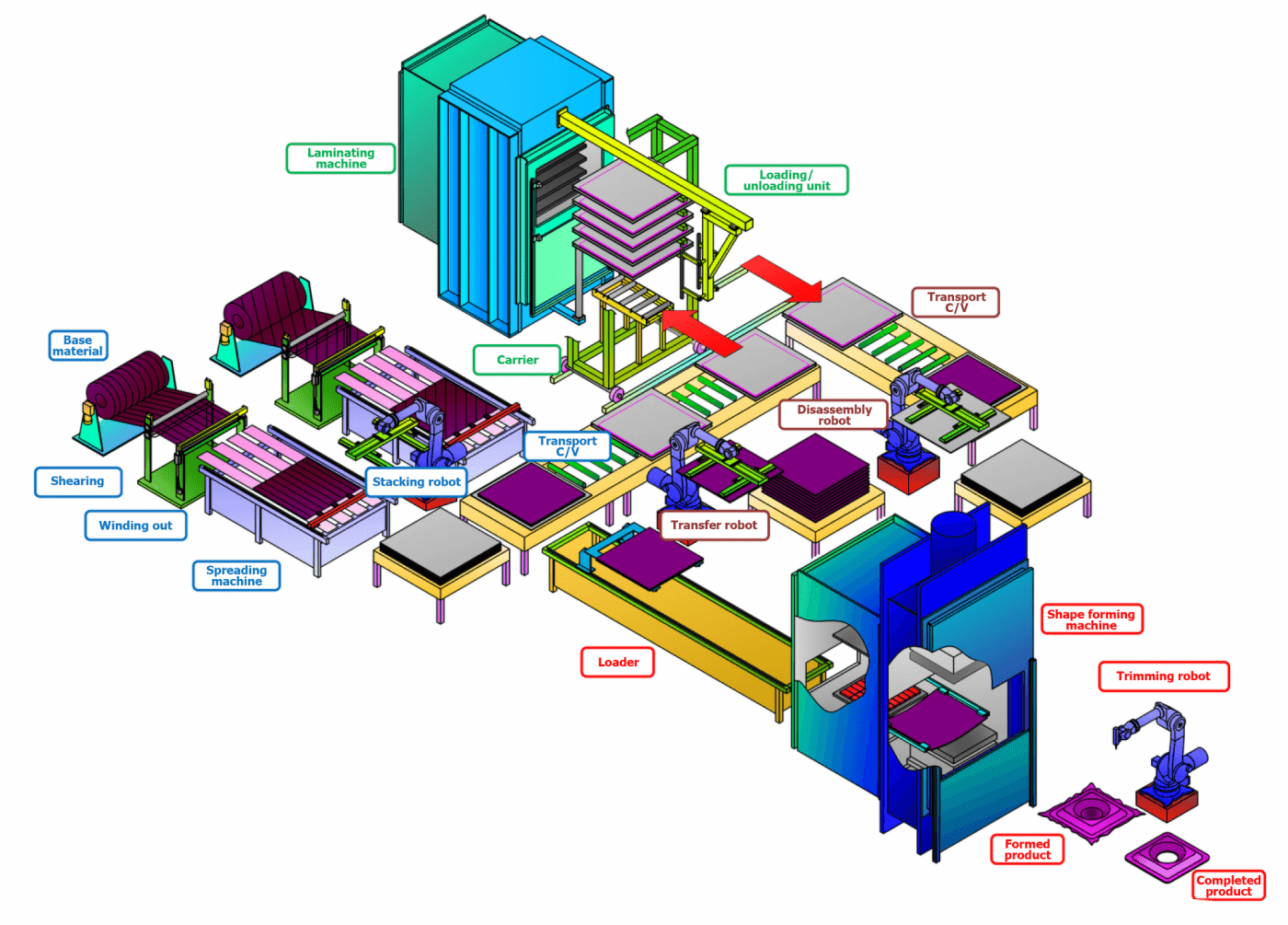

CFRP stacking and laminating line

Cutting and joining area

Joining sheet size | 800 mm square to 1,200 mm square |

Conforming material | C (G) FRTP-UD tape Width: 150 mm to 330 mm (6 inches to 16 inches) Thickness: Approx. 0.1 mm to 0.3 mm |

Cutting angle setting | 45 to 90° (arbitrarily settable) |

Joining temperature | Max. 330 °C |

Stacking area

Conforming sheet size | 800 mm to 1,200 mm square *Also available for various materials such as cloth and non-woven resin sheets, etc., in addition to “arbitrary angle-oriented sheets.” |

Sheet material stock | 4 locations (can be expanded) |

Cutting angle setting | Adsorption pad (can be changed) |

Stacking temporary fixing | Ultrasonic welding 4 points (can be changed) |

With press plate feed function |