What is a multi-opening press?

2022-03-01

Kitagawa Seiki’s specialty multi-opening vacuum press

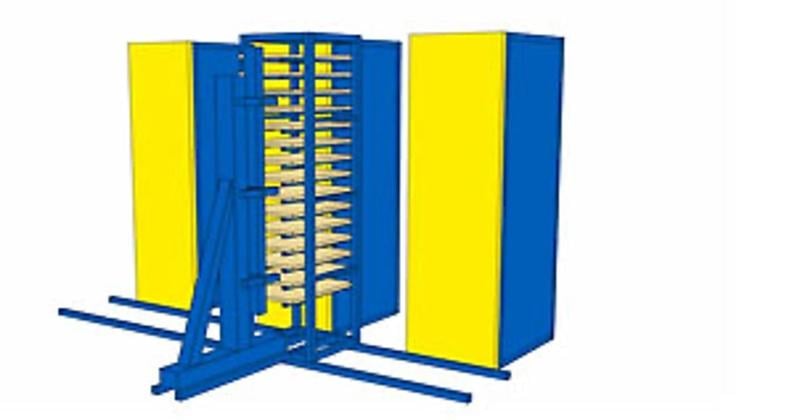

The multi-opening vacuum press (also called a multi-opening flat plate hot press) of Kitagawa Seiki’s main product is a hydraulic press machine that specializes in laminating sheet materials, and has features different from a hydraulic press of a forge rolling machine used for sheet metal working.

For the flat plate hot press, plate-like heating metal molds called Heating plates are preset on the upper and lower platens of the press, and sheet materials are sandwiched between these Heating plates, and are then attached together by pressing by the press while heating.

For the multi-opening press machine, multiple openings (=opening into which products are loaded) of the press machine which sandwich materials are provided by arranging Heating plates in the middle in addition to upper and lower Heating plates.

In addition, occurrence of bubbles at the time of laminating and oxidation of the materials can be reduced by using a vacuum press which can form in a vacuum atmosphere while storing the pressing part (normally, entire Heating plates) of the materials in a chamber which can be depressurized.

Features of multi-opening press machine: “High degree of productivity”

For attaching sheet-like materials, a flat plate press or a roll press for continuous production can be used. However, product quality by a roll press will not reach the level of a batch type flat plate press in terms of high flatness accuracy and dimensional accuracy, and uniformity of heat and pressure history.

The multi-opening press machine was designed to be able to form multiple products simultaneously for increased productivity with the same product quality as the batch type flat plate press.

When attaching using thermosetting resin, heating and pressing for the specified time are required until the resin is hardened, so laminating time cannot be shortened.

The multi-opening press machine can increase productivity through simultaneous laminating by using multiple openings.

Furthermore, for attaching thin layer materials, multiple laminating products are stacked and loaded in one opening, and products of the number of openings × loading number can be produced simultaneously. If materials for 20 products are loaded for each opening of a 20-opening press, 400 products can be formed at one time.

The multi-opening press machine is used mainly for printed circuit boards.

Currently, the multi-opening vacuum press machine is used mainly for printed circuit boards.

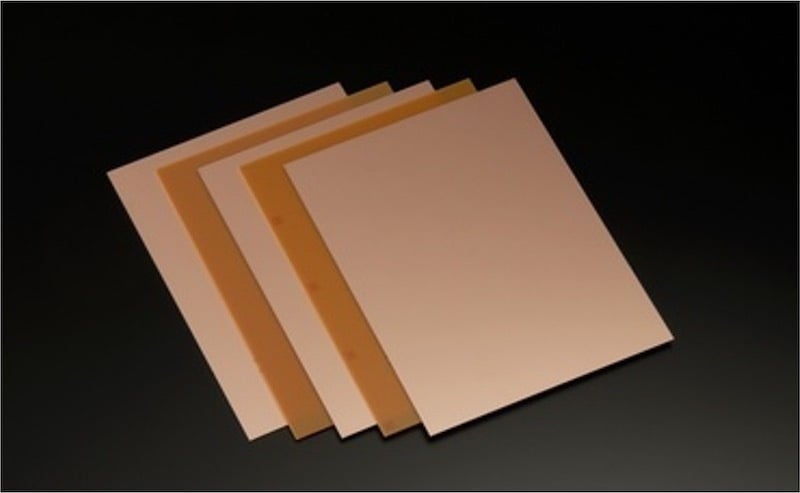

A printed circuit board is absolutely essential to electronic devices. The multi-opening vacuum press machine is used to produce copper-clad laminates (CCL) which is a material of the printed circuit board. Also, this press machine attaches prepreg (sheet which is made from glass cloth (insulation layer) impregnated with thermosetting resin such as epoxy) and copper foil.

The large multi-opening vacuum press machine with a Heating plate size of more than 1m × 2m and which has 10 or more openings, or 20 or more openings is used.

The multi-opening vacuum press machine is also used in the multi-layering process where electronic circuits are printed and etched on this CCL and then insulation layer and copper foil are stacked.

Highly multi-layered printed circuit boards with more than 50 layers are used for base stations of mobile phones and supercomputers which are essential to our modern information society, and extremely high precision is required for its lamination. Our multi-opening vacuum press machine plays an active role in this field.

Other applications

Other than printed circuit boards, multi-opening press machines are also used for film laminating and resin sealing for sensors and heaters, and production of resin plates and rubber products by using metal molds.

Conventionally, large non-vacuum press machines have been widely used for production of plywood and decorative plywood such as veneer boards, sliced veneer and melamine boards, and sandwich panels and other building materials and structural materials.

Research and development have been conducted to apply multi-opening press machines to laminating of thermoplastic CFRP laminates which are light-weight material and have recently attracted attention, and future advancements are expected.