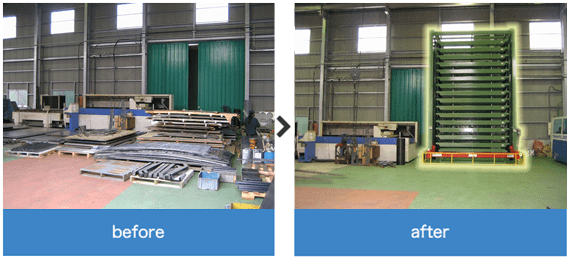

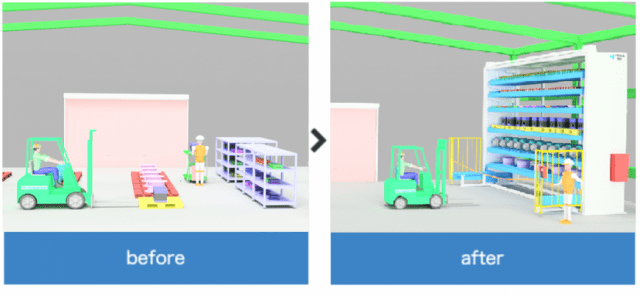

Contributing to space-saving and inventory management

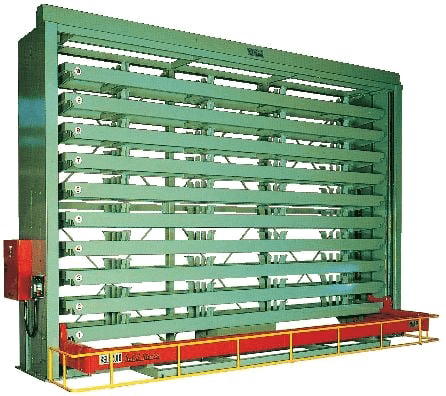

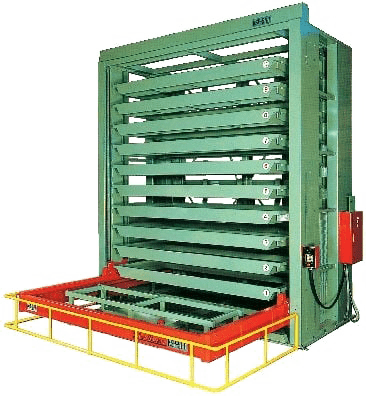

Heavy items of mainly steel materials which take time to transport and store can be compactly stored, and transportation and storage can be automated.

The stocker can be used for storage of steel materials and steel plates, etc. We manufacture according to each customer's needs

We manufacture according to each customer's needs, so please contact the Kitagawa Seiki’s sales staff.